Here at blackbird we are experienced in working in the energy generation and manufacturing sectors.

Our UAV’s can carry out inspections quickly and efficiently, ensuring you get the data you need without incurring large access costs and risk associated with working at height.

Using the latest UAV’s we can provide feedback on the condition of your plant/equipment allowing you to make quick decisions when it comes to reactive and planned maintenance.

In scenarios with operating plant we have high specification cameras with up to 180x zoom capacity allowing for millimetre detail while maintaining safe working distances.

The major benefits being the reduction in downtime and increase in safety, allowing inspections to be carried out on live equipment from a safe working distance without the need for any contact.

If equipment does need to be shut down our well experienced team are able to carry out the mission quickly and efficiently ensuring your productivity losses are minimised.

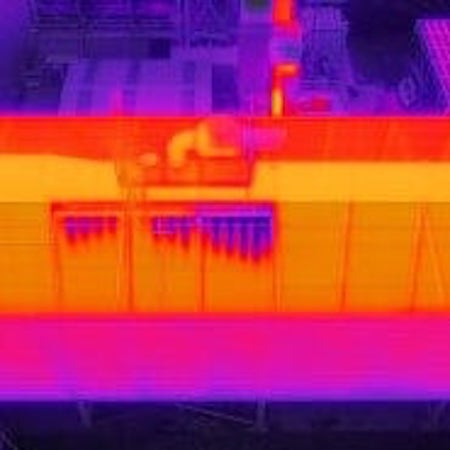

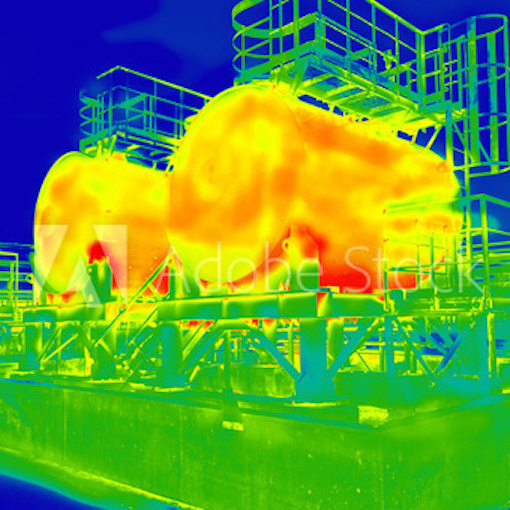

Both thermal and photographic surveys can be carried out, providing high resolution images and 4k footage to allow us to provide you with a clear & measurable view of your equipment.

All of our surveys are geo-referenced, and our state-of-the-art software allows us to build 3D models to interrogate & measure defects.

Some of our previous applications of our services are:

We work closely with customers to come up with the ideal for solution for them regardless of the type of equipment. If you would like to discuss your specialist application, please do not hesitate to contact us

UAVs equipped with high-resolution cameras can capture images of even the smallest defects

UAVs equipped with the latest thermal cameras can assess the condition of a wide range of equipment, including wind turbine blades, electricity distribution plant, and other machinery

Our UAV-mounted thickness testing equipment is able to ignore coatings up to 20mm thick

Large confined spaces such as storage vessels and furnaces can be safely inspected using the latest uav technology.

We deploy UAVs fitted with optical gas imaging cameras to detect gas leaks, aiding compliance with environmental regulations and increasing profitability

In certain applications LIDAR can provide useful supplemental data to an optical or thermal survey, generating highly precise models of surfaces or terrain.

There are plenty of benefits to drone surveying, here's just a few

Many UAV surveys can be safely conducted on live equipment, reducing lost revenue during the inspection window

Even where isolation is necessary, preparation and inspection times are significantly shorter than traditional inspection methods

Significantly reduces the need for personnel working at height

All inspections are conducted with the latest UAVs, incorporating rotor redundancy and collision avoidance features to ensure the safety of equipment and personnel

State of the art cameras and sensors produce high resolution images, enabling accurate condition monitoring and remedial work planning

Reduced cost and inspection times vs. traditional methods allows more frequent inspections

Repeat readings at regular intervals allows precise tracking of equipment condition and deterioration over its lifespan

Combination of optical and thermal analysis is able to identify a wide range of potential blade issues

Cloud-based data storage and interrogation tools allow clients to interpret data from anywhere in the world

Sophisticated software enables comprehensive reporting, highlighting any defects on precisely georeferenced images

Intelligent inspection software enables easy repetition, to monitor the rate of equipment degradation

All defects can be measured accurately using inspection software, enabling assessment of fault severity and planning of remedial work

We have a deeply experienced team, a wide range of state-of-the-art equipment, and a broad range of UAV inspection services to deal with any situation. We work closely with all our clients to come up with the ideal inspection package for their requirements and budget.